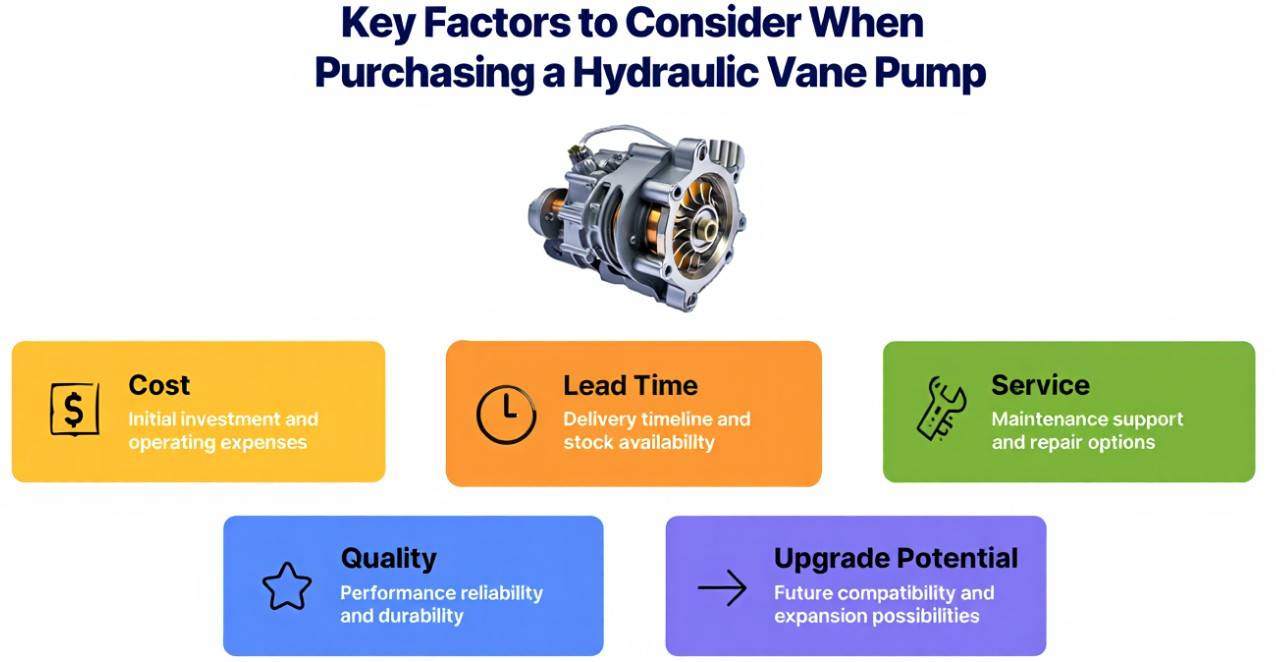

5 Key Factors to Consider When Purchasing a Hydraulic Vane Pump: Cost, Lead Time, Service, Quality, and Upgrade Potential

In industrial automation and machine tool manufacturing, hydraulic systems play a vital role in achieving power precision, motion control, and long-term reliability. Selecting the right hydraulic pump supplier goes beyond the basic question of price — it involves evaluating overall performance, service continuity, and adaptability for future needs.

For procurement managers and OEM clients, these five key factors—cost, lead time, service, quality, and upgrade potential—serve as the foundation for reliable sourcing decisions. Let’s explore how these considerations can shape a long-term partnership, and why ANSON HYDRAULICS INDUSTRIAL CO., LTD. stands out as a trusted manufacturer in the global hydraulic industry.

1. Cost: Beyond the Initial Price Tag

Balancing Purchase Price and Lifecycle Value

In procurement, cost is always a decisive factor—but a short-term saving may not always translate to long-term value. A high-quality hydraulic pump, precisely machined and tested for pressure consistency, can significantly reduce downtime and maintenance costs over years of operation.

ANSON HYDRAULICS helps clients optimize cost efficiency through design standardization, modular components, and energy-efficient pump solutions that minimize total ownership cost. This ensures every investment delivers lasting performance instead of repeated replacements.

2. Lead Time: Ensuring Supply Continuity

Reliable Delivery Supports Business Growth

Lead time has become a critical differentiator in global sourcing. A delay of even a few weeks can impact production schedules and delivery commitments to end customers.

ANSON’s integrated production system and Taiwan-based manufacturing hub enable precise lead-time management. With advanced inventory planning, flexible batch production, and experienced logistics coordination, ANSON helps OEM partners maintain predictable supply cycles—especially in high-mix, low-volume production environments common to machine tool and equipment manufacturers.

3. Service: A Total Support Experience

Pre-Sale, After-Sale, and Technical Support

Procurement is not just a transaction—it’s a relationship. A dependable supplier provides assistance at every stage, from product selection to system integration and after-sales service.

ANSON HYDRAULICS has built its global reputation through comprehensive customer service. The company’s engineers assist clients in selecting pumps suitable for various hydraulic systems, offer consultation on energy-saving configurations, and provide quick-response after-sales support to minimize downtime.

This “total service solution” approach positions ANSON as more than a supplier—it’s a partner invested in every customer’s success.

4. Quality: Precision Engineering for Lasting Performance

Proven Quality through Manufacturing Excellence

Hydraulic systems operate under extreme pressure and precision tolerances, which means every component must meet exact performance standards.

ANSON’s manufacturing excellence stems from decades of precision machining experience. Each hydraulic pump undergoes strict quality control, including pressure testing, leakage inspection, and endurance validation. The result is reliable performance under continuous industrial use—from CNC machine tools and forming equipment to automated production lines.

Consistency Builds Trust

By maintaining in-house R&D and manufacturing, ANSON ensures consistent quality across every production batch. This control over the entire process—from material sourcing to assembly—builds long-term trust with OEMs, distributors, and end users worldwide.

5. Upgrade Potential: Preparing for the Future

Flexibility and Customization for Evolving Needs

As automation technologies advance, buyers increasingly seek hydraulic systems that can be upgraded or customized for future performance requirements.

ANSON HYDRAULICS integrates R&D innovation into every design stage, offering customizable configurations, optional control interfaces, and energy-saving mechanisms compatible with smart factory standards. Clients benefit from solutions that can evolve with their production technology, reducing replacement costs and enhancing operational flexibility.

Building a Long-Term Partnership with ANSON HYDRAULICS

Purchasing a hydraulic pump is not just about selecting a product—it’s about choosing a supplier you can rely on for years of consistent service, performance, and technical support.

By focusing on cost efficiency, on-time delivery, responsive service, uncompromised quality, and upgrade-ready design, ANSON HYDRAULICS offers unmatched value to global OEM clients and machine tool manufacturers.

With a full-service model that combines design consultation, manufacturing, testing, and technical assistance, ANSON stands as a trusted partner in building smarter, stronger hydraulic systems worldwide.

Why Choose ANSON HYDRAULICS?

-

Over 30 years of experience as a professional industrial hydraulic pump manufacturer

-

Comprehensive product range including vane pumps, piston pumps, hydraulic power units, and system components

-

ISO-certified manufacturing and 100% product testing for performance assurance

-

Flexible OEM/ODM services tailored to customer requirements

-

Global support network and prompt delivery from Taiwan

Partner with ANSON HYDRAULICS Today

When reliability and efficiency define your business success, choose a supplier that shares your commitment to performance excellence.

Contact ANSON HYDRAULICS INDUSTRIAL CO., LTD. today to discuss your hydraulic system requirements and discover how our total service solution can empower your next project.